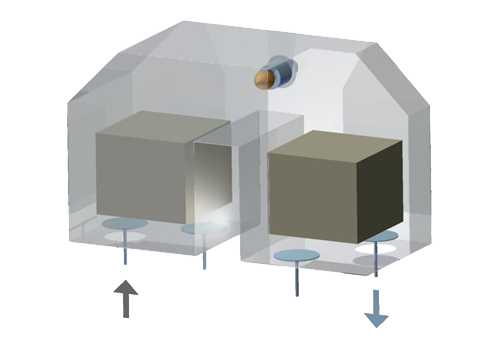

Regenerative Thermal Oxidizer - RTO

Waste gas passes through the ceramic bed into the oxidation chamber where the oxidation of volatile organic compounds takes place. Hot clean air releases thermal energy while passing through the ceramic bed of the heat exchanger. This energy is recovered and used further in the system, considerably reducing fuel consumption and consequently operating costs as well.

The equipment features the following properties:

- High VOC destruction efficiency (> 99%),

- High thermal energy recovery (> 95%),

- Low pressure drop,

- Low operating costs.

The equipment is suitable for:

- Air volumes up to 100,000 m3/hour,

- A wide spectrum of pollutants,

- A wide range of VOC concentrations.

Photogallery

Case studies

Need to control the air pollution?

Get in touch