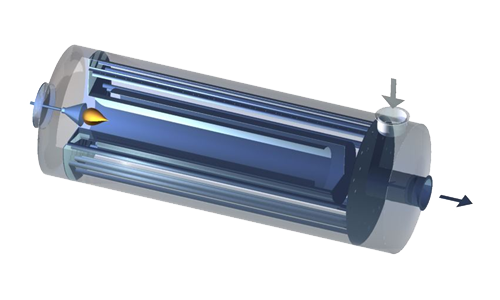

Recuperative Thermal Oxidizer

With the use of a fan, waste air is discharged into the equipment, where it is pre-heated in the recuperative thermal heat exchanger. Usually, this is a shell-and-tube type heat exchanger. The contaminated air then passes through the oxidation chamber where the oxidation temperature is achieved with the use of a burner. There the oxidation reaction takes places, and pollutants are converted to water vapor and carbon dioxide. Hot clear air then passes through the heat exchanger again, where the inlet air is pre-heated. The heat exchanger therefore reduces fuel consumption.

The equipment features the following properties:

- High VOC destruction efficiency (> 99%),

- Removing of high concentrations up to 20% LEL.

The equipment is suitable for:

- A wide spectrum of pollutants,

- Smaller or medium-sized air volumes.

Photogallery

Need to control the air pollution?

Get in touch